From Flow Rate to Percentage-Based Gas Mixing

Explore the benefits of shifting from flow-rate to percentage-based gas mixing, achieving unprecedented precision and ease of use.

One of the best benefits we bring to our customers, it’s a fresh perspective that breaks free from the norm. Imagine moving away from the complicated world of flow rates and adopting a better one, where precision meets simplicity—the world of percentage-based operation.

Our Gas Mixers offer scientists and operators a level of control that’s not just revolutionary, but also remarkably easy to wield with just a few clicks.

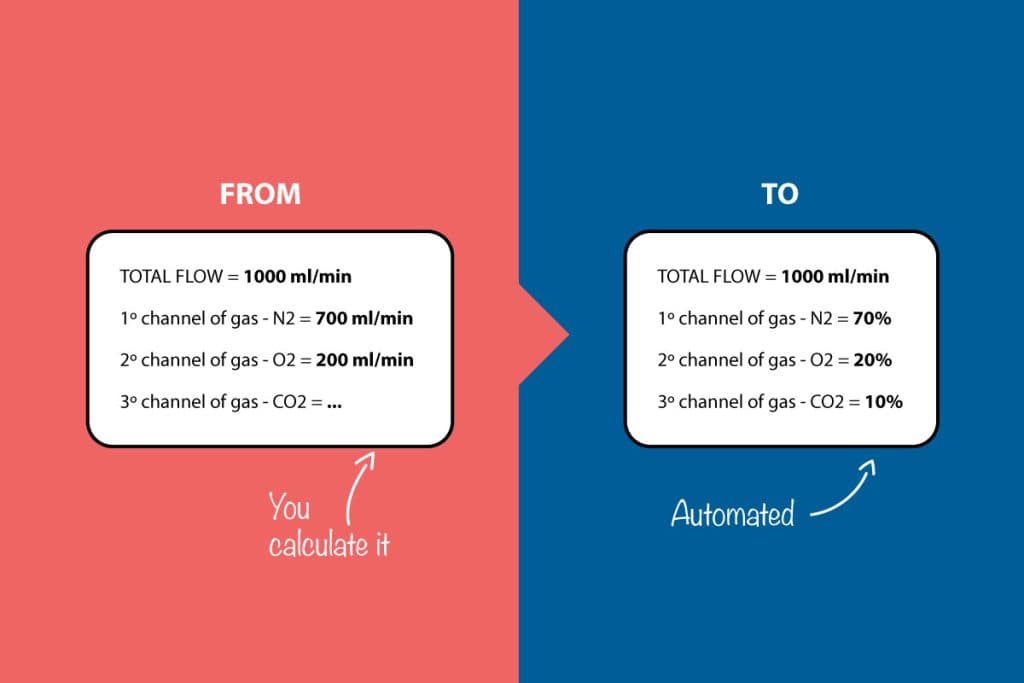

Traditionally, to be able to generate tailored gas mixtures, it has been the norm the suffer from complexities. Spreadsheets and laborious calculus were needed to input the right amount of flow rate for every single gas.

But we’re rewriting the script. Gas Mixers introduce a game-changing approach where percentages take the spotlight. It’s not about intricate calculations and convoluted processes; it’s about setting the total flow and defining the percentage of each gas—simple as that.

The Gas Mixer then takes the reins, autonomously crunching the numbers for each channel. This shift is more than just a change; it’s a revolution in user-friendly precision.

INNOVATIVE GAS MIXER

Percentage-Based Operation: A Game-Changer

Gas Mixers operate on a percentage-based model, setting them apart from traditional flow-rate systems. Scientists and operators now have the ability to effortlessly set the total flow required and define the percentage of each gas in the mixture.

The Gas Mixer then autonomously calculates the precise flow for each channel. This revolutionary shift eliminates the need for cumbersome spreadsheets, making the entire process remarkably user-friendly.

Let’s delve into real-world examples to grasp the sheer power and simplicity of this approach:

Example 1:

Crafting a Gas Mixture (N2 70%, O2 20%, CO2 10%) with a Total Flow of 1000 ml/min

With our Gas Mixer: Set the Total Flow to 1000 ml/min in the designated box. Navigate to the O2 channel, input 20%, proceed to the CO2 channel, input 10%, and automatically, the balance becomes 70%. Done! Click Start Flow.

With a Mass Flow Controller (MFC): Navigate through each channel, and set individual flow rates (700 ml/min for N2, 200 ml/min for O2, and 100 ml/min for CO2), requiring a meticulous understanding of flow and concentration equivalences. This often involves complex spreadsheet work that can be time-consuming and prone to errors.

example 2: FLEXIBILITY

Scenario 1: Flow Adjustment to 1500 ml/min

With our Gas Mixer: Simply update the Total Flow to 1500 ml/min. Done.

With an MFC: Revisit the Excel sheet, recalculate for the new flow, and manually update each channel. A tedious and error-prone process.

Scenario 2: Changing CO2 Concentration to 0

With our Gas Mixer: Modify the CO2 row to 0. Finished.

With an MFC: Open Excel, recalculate the values, and manually update each channel to achieve the new percentages. A time-consuming endeavor.

Scenario 3: Changing Both Flow and Concentration

With our Gas Mixer: Achieved with just 4 clicks.

With an MFC: A complex and intricate process requiring adjustments to both flow and concentration on each individual channel.

In conclusion, the era of precision-based gas mixing has arrived, spearheaded by Gas Mixers operating in percentages. This revolutionary approach not only simplifies processes but also enhances accuracy, providing a seamless experience for researchers and operators. While traditional methods may seem convoluted, Gas Mixers redefine the landscape with unparalleled simplicity and efficiency. Say goodbye to complexities; welcome the future with just a few clicks.