GB IVF Gas Mixer for In Vitro Fertilization

No Buffer. Small.

A Gas Mixer designed specifically for IVF - In Vitro Fertilization processes. It offers precise control and blending of N2, O2 and CO2 or simply diluting Air from the wall-mounted pipe, all with automation and an Auto-Purge mode for added convenience.

Auto-Purge - Compact - Dedicated Software

3 Pure Gas Inputs

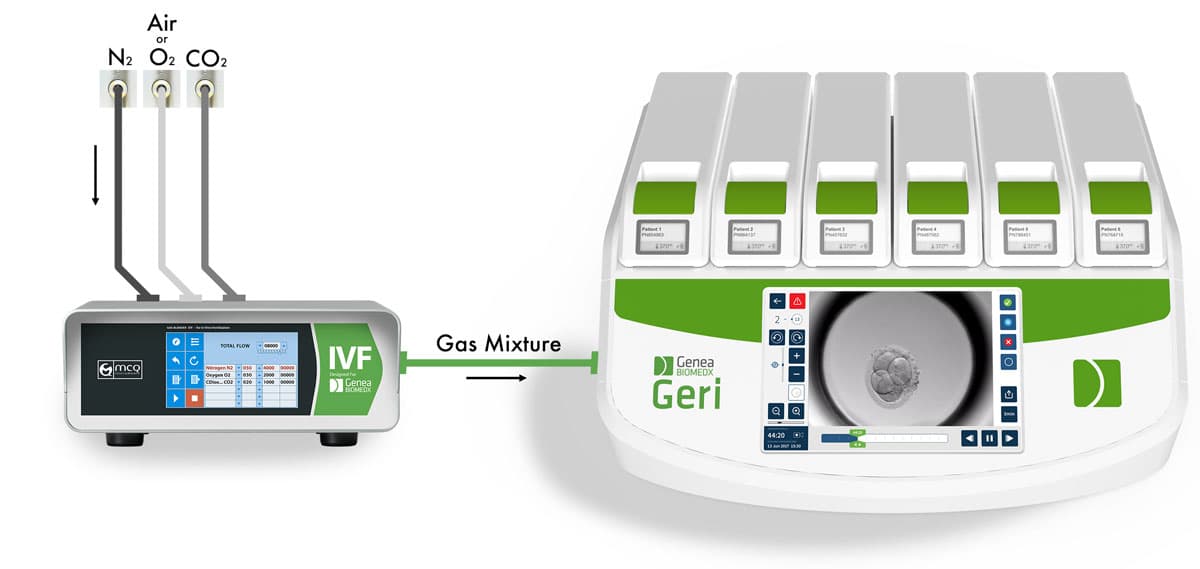

Multi-System Incubator

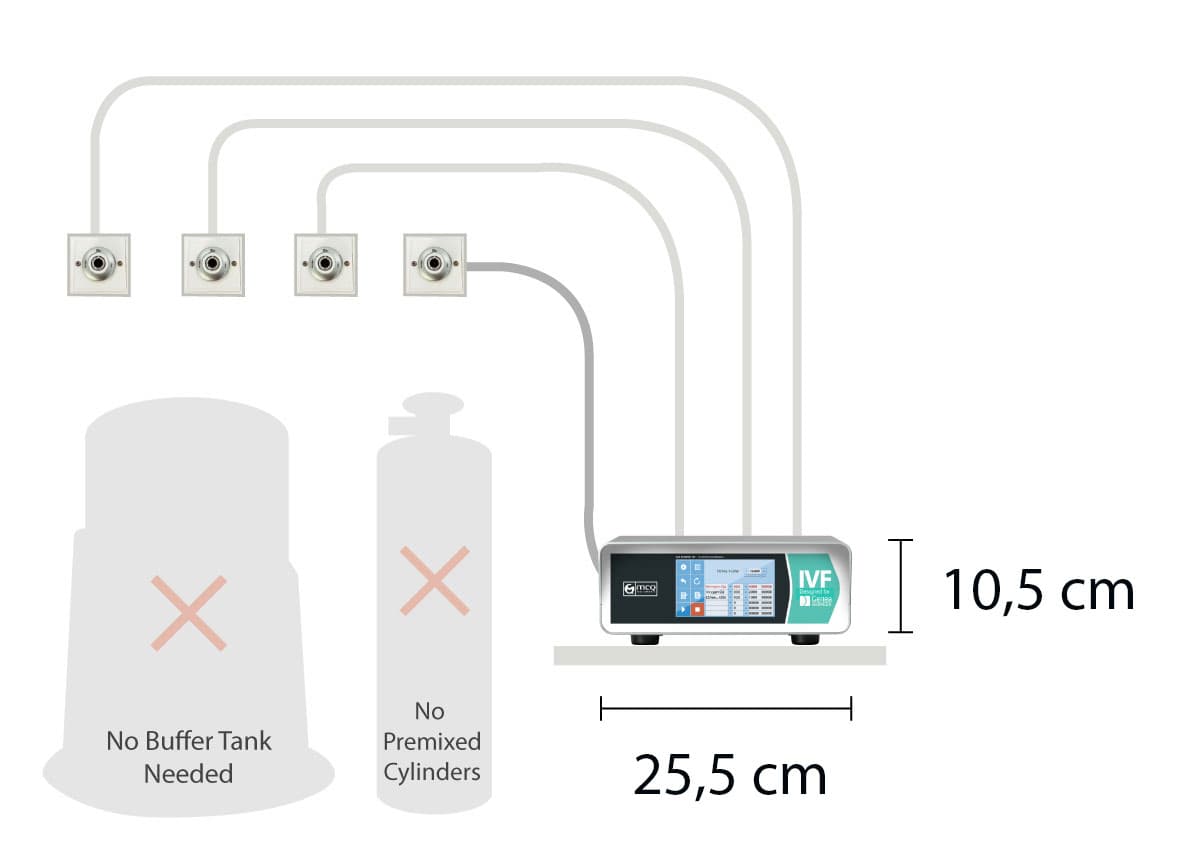

This gas mixer utilizes a novel gas-mixing technology based on unique physicochemical properties. This innovative approach eliminates the need for frequent calibrations, streamlining your workflow. Additionally, the mixer is a self-contained unit, eliminating the requirement for a separate buffer - simply plug and play for immediate use in your lab.

Learn more about our collaborations.

REQUEST DEMO

Custom Firmware and Software with Auto-Purge.

Our IVF-optimized gas mixer with custom software and firmware offers significantly more control over your culturing process compared to traditional Gas Mixers.

Set your desired gas mixture composition (example 5% O2, 6% CO2), and our advanced algorithm monitors for potential disruptions

No Buffer Cylinder Required

Unlike traditional IVF gas mixers that rely on cumbersome buffer cylinders and require constant sensor calibration, our Gas Mixer offers a complete, ready-to-use solution.

Forget the need for external buffers! Say goodbye to frequent recalibrations. Simply connect pure gas cylinders or utilize your existing air supply.

IQ OQ GMP Ready.

We ensure adherence to rigorous manufacturing processes through a comprehensive validation system: Our “IQ OQ GMP Ready” slogan reflects our unwavering commitment to quality and compliance.

Multiple Incubator Connections

A single GB IVF gas blender can support several incubators at once. The number of connected units depends on the incubator brand and system specifications.

Ready to Use System

REQUEST DEMOSimplify Your IVF Lab

No Premixed Gas Cylinders are required! The Gas Mixer can be used to manage the flow of pure cylinders of N2, O2, and CO2 in order to create specific conditions in your needs.

Additionally, the Gas Mixer enables the dilution of Air from your existing air supply to attain the desired gas composition.

A New Gas Mixing Technology.

You don't need any additional hardware or IT specialist to configure our system. At the heart of our IVF gas mixer lies a revolutionary technology that sets it apart from conventional systems.

Unlike traditional mixers that rely on gas sensors in each channel, requiring frequent and complex calibrations, our system utilizes an engineered flow control system based on mass flow principles.

Operate using percentages of gas, not just in flow rates

Complete and Ready-to-use System

Superior alternative to Pre-Mixed gas cylinders

MCQ Instruments provides bundled software with all of its devices for full automation. Our instruments are designed to control every parameter, from the individual components of a gas mixture to the management of the entire process.

Datasheet

GB IVF

Our all-in-one up to 3-channels solution for gas mixing

O2 and CO2 Range

O2 from 0,1% to 100,0%

CO2 from 0,1% to 100,0%

N2, O2, CO2, Air

Additional gases supported on request

Accuracy

Accuracy on O2: 0,1%

Accuracy on CO2: 0,1%

Repeatability

0,10% of reading

Response time

100 ms for each channel

More

Power Supply

In Bundle

Operation Pressure

Max 3 bar

Working Temperature

15 - 25 °C

Compatibility

Profibus, Modbus, Matlab Simulink, Python Library

Communication

USB PC Interface RS485 with open proprietary protocol.

Fittings

Push-to-Connect fittings for 6 mm tubes. Other on request.

Inlet Gas Channel

3 Inputs

Outlet Gas Channel

1 Output of mixed gases

User Interface

Gas mixing software. Touch Display

Certifications

CE, TUV, cTUVUS, Made in Italy

The Gas Mixer for Laboratory

A complete laboratory experience in a single, ready-to-use box.

ProfiBus, Modbus, Matlab Simulink compatible. USB and RS485 Bus. Python Lbrary supplied

Create Custom Gas Mixtures starting from Pure Gas

No specific skills are required. No Extra Hardware, No IT Specialists

Informative Data and Downloads

Normothermic Ex Vivo Liver Perfusion

Easy blending of gases, runs without user input (Programmable sequences).

Oxygen regulated microscope perfusion system

The immediate availability of any gas mixture required (5% CO2, 0-18% O2) is a potentially substantial time saving feature, as ordering custom gas mixtures can take 1 month.

Hypoxia Studies

Running experiments is easy and straightforward.

Help Me Choose

Answer a few questions to find the best Gas Mixer for you.

Interactive Guide